|

How To Make Full Use Of Blue Ring Tester

The reason I write this article is because I often get emails from Blue Ring Tester buyers that they wanted help in the form of photos to guide them how to use the tester. My job here is to simplify the process of testing the coils with the tester and hope this article could help them to fully utilizing this meter for troubleshooting purposes.

So what is a Blue Ring Tester?

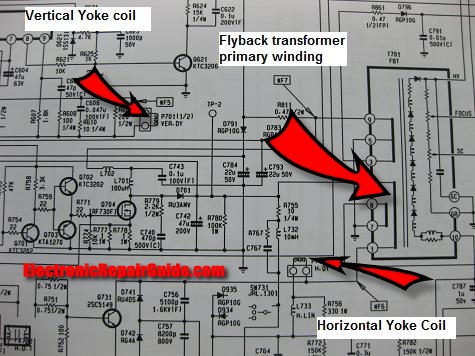

The Blue ring tester is an inexpensive and effective way to test any high Q inductive component. It is especially useful for doing a quick check on Flyback Transformers, B+ coils and other high frequency inductive components like Horizontal deflection yoke windings and SMPS transformers. In other words the Blue Ring Tester is also a Coil Tester or a Shorted Turn Tester How does the ring tester work?

The components in many circuits including display drivers, SMPS and tuning circuits contain low loss (high Q) resonant circuits. The testing technique used in this design is based on the fact that many faults in magnetic components result in increased loss = reduced Q. Ring testing gets its name from the fact that a when fast voltage pulse is applied to a high Q circuit the tuned nature of the circuit will produce a decaying AC voltage of several cycles. More cycles, or “rings”, mean higher Q. Few or no cycles indicates a problem in that component, a shorted winding or some other malady. This tester provides a quick and easy way to track down such problems. Why do we need Blue Ring Tester to test coils instead of using Ohmmeter and Inductance meter? If you use an ohmmeter or even an inductance meter to test a coil/winding then chances is very high you will not be able to repair the equipment. Why? Because both meters could misled you into believing that a shorted coil/winding is good! That means a coil with shorted turns in the winding could still show you a good Ohm reading and good Inductance value too. If you miss those bad coils during troubleshooting then the rest of the time you use to troubleshoot on other area or components will be wasted because the actual problem is in the coil.

What this tester can do

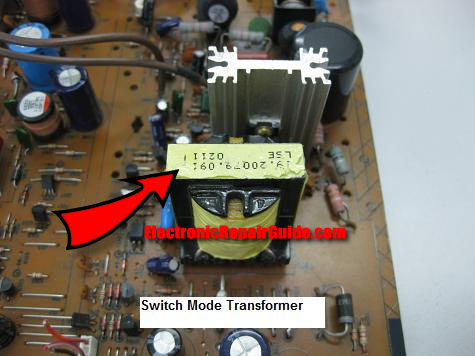

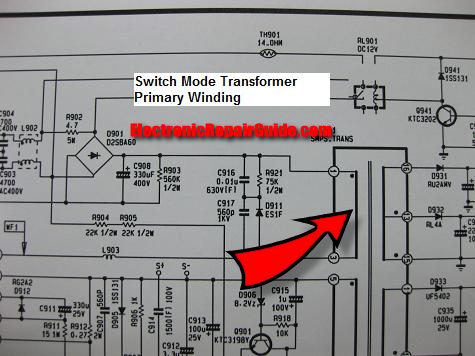

1) Check the primary winding of switch mode transformer in any electronic equipment.

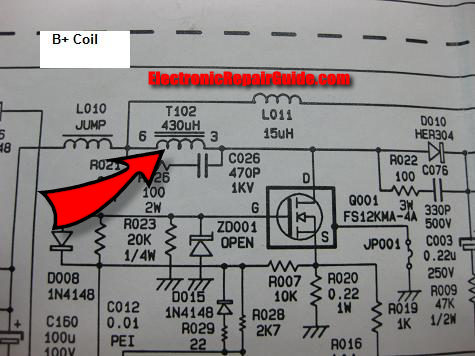

2) Check B+ coil in CRT Monitor

Note: For your information B+ coil could also come in the shape like a horizontal driver transformer

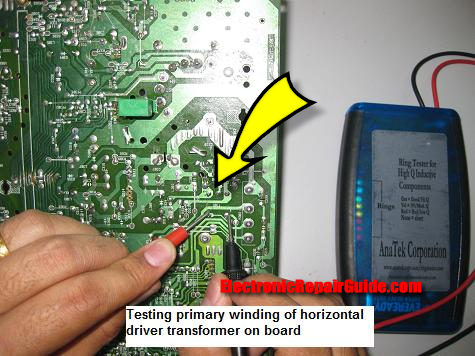

3) Check the primary winding of Horizontal driver transformer in CRT Monitors/Tvs

Click Here To Purchase The Blue Ring Tester

4) Check the primary winding of flyback transformer in CRT Monitors/Tvs

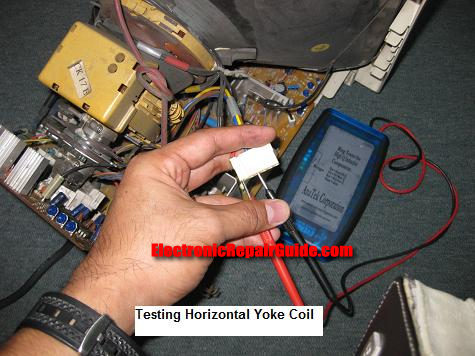

5) Check horizontal yoke coil windings in CRT Monitors/Tvs

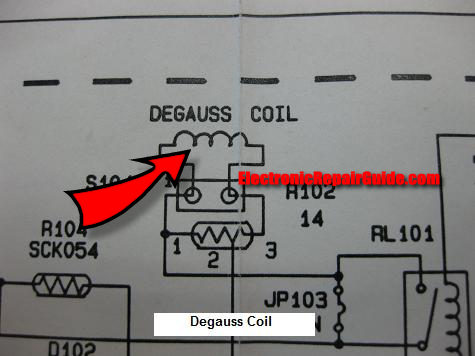

6) Check the degaussing coil in CRT Monitors/Tvs

6) Check the ballast of fluorescent lamp

7) Check the Primary and Secondary Winding Of Linear Transformer

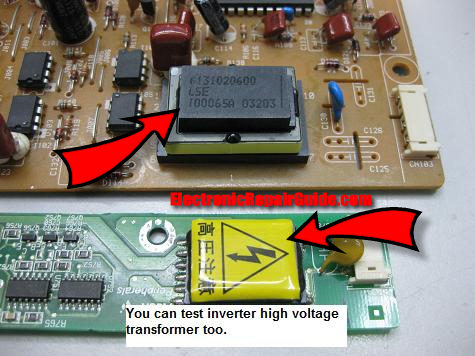

8) Check the high voltage transformer in LCD Inverter board

What this tester can’t do

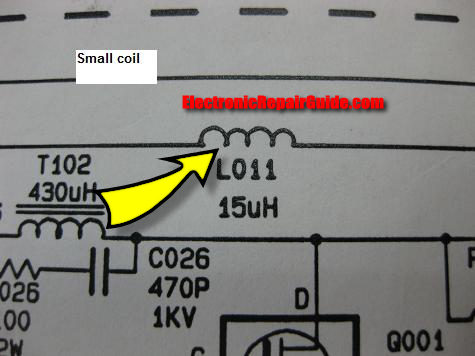

Generally the higher the inductance value the more LED from the tester will light up, assuming if there is no shorted turn in the winding. In other words it can be used to check on coils that have at least .3milihenry and above. If the value is lower than that then there will be less LED will light up and sometimes the LED may go off too. Usually the smaller the coil, the smaller will be the inductance value. Below are the components that this tester can’t test:

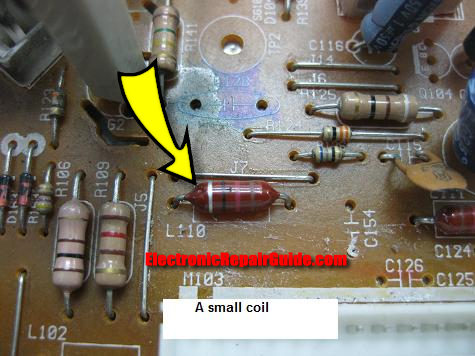

1) It can’t be used to check on small coils and ferrite bead because the inductance value is too small.

2) It can’t be used to check on vertical winding in CRT Monitors/Tvs because the vertical winding is usually too low Q to respond to any ring tester.

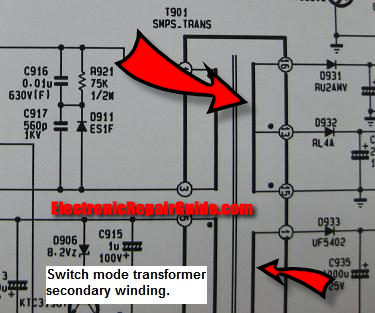

3) It can’t be used to check on secondary winding of Switch mode and Flyback Transformer in CRT Monitors/Tvs because the inductance value is too small.

Is this the best tester to test a coil-does it has 100% accuracy?

The best tester to test a coil or any other components is the equipment itself. The reason for that is because the components (including of the coil) will go through all actual signals (voltage, current or frequency) which any tester in the world also could not provide. For your information all components (which include the coils) can breakdown when under full load thus no tester can claim to have 100% accuracy to really test components unless the tester can actually apply all the right signals to the components when under test.

Components that breakdown when under load is not very common thus you should not worry about this. Assuming if you have doubt on the coil that you have tested with the Blue Ring Tester, just directly replace and retest the set. You may also compare the coil reading with another similar or quite similar machine for best result. For example, if you are a seasoned repairer for LCD TV, then you should roughly know the reading of the primary winding of switch mode transformer (in power board) and the windings of the high voltage transformer in the inverter board.

Conclusion- Blue Ring Tester is a MUST for those of you who is in the electronic troubleshooting line. It has the capability in testing coils in-circuit (without removing the coil out from the circuit) thus saving your repair time. It is easy to test the coils because the test leads are non-polarized-that means you can test the coils using either way from the test probes and directly read the result from the lighted LEDs. Lastly, it is affordable too as compare to the price of the industrial type of winding tester in the market which can cost several thousand dollars.

Click Here To Purchase The Blue Ring Tester

Click Here To Learn How You Can Be A Professional In Switch Mode Power Supplies Repair

Click here to learn how you can become a Professional in Testing Electronic Components

Click here to learn how you can become a Professional in LCD Monitor Repair

Recommendation:

Recommended Mr Steve Cherubino Laptop Repair Videos For Beginners!

Recommended Mr Kent Projection Television Repair Membership website-Visit Now!

Recommended Mr Kent LCD TV Repair Membership website-Visit Now!

Recommended Mr Kent Plasma TV Repair Membership website-Visit Now!

|

|

Copyright@ 2006-2014-www.ElectronicRepairGuide.com All Rights Reserved