Electronic Components That Breakdown When Under Full Operating Voltage

Have you ever come across any case where you could not locate the fault even if you have already spent countless hours in repairing the equipment? In order for you to easily understand the question above, let’s take this as an example. You have confirmed and very sure that the power primary side is having problem after done some test but you just could not find out the faulty parts. You have checked every single component on it and even the power IC you have replaced and yet the equipment still won’t work and in some cases the main fuse may blow too. You are wondering why after learned so many tips and techniques about electronic repair and still not be able to solve the problem? You never give up and continue to recheck again all the electronic components and do all sort of testing and at the end the equipment still would not work. Frustration and giving up are the only words that are playing in your mind. Let me tell you my friend; don’t give up as there is hope to solve this kind of problem.

For your information, the scenario above does not limit only to power section, it could also happen in any kind of electronic circuits such as vertical, horizontal, color, high voltage and etc. The reason why you can’t locate the faulty parts is because those electronic components were breaking down when under full load or operating voltage. That’s mean, if no appropriate voltage or signal applies to the components, it will test good or check to be okay with your multimeter (analog or digital) or with any kind of testers that you have for the components you want to test. If a full operating voltage and signal applies to the components (just when you switched on the equipment), the components will start to behave strangely such as shorted, open or even leaky and this is what we call as “electronic components that breakdown when under full operating voltage”.

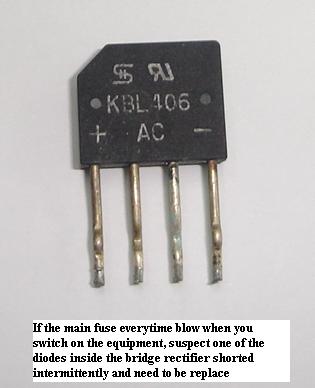

Okay let’s talk about the bridge rectifier first. I myself encountered few before many years back where the bridge rectifier tested good with an analog multimeter (set to x 10 k ohm range) but when the power was switched “On” the main fuse blow immediately. Checking the surrounding components found no trace of any shorted components in the primary and secondary side. So I decided to replace the bridge even though it tested good with my meter, to my surprised the Monitor works. I began to examine the faulty bridge rectifier again but now test with a digital meter. The result that I got was still showing good! No wonder in the market there are companies that sell a special tester just for checking diodes. Our normal meters just don’t have enough capability to check all kind of diodes. Fortunately this kind of problem doesn’t happen very frequent. For your information, a defective posistor in Monitors also can cause similar problem. The best is to direct replace the posistor and retest the Monitor again. In order to avoid the fuse from blowing again, you can always connect a 100 watt light bulb in series with the fuse holder (the fuse has to be removed).

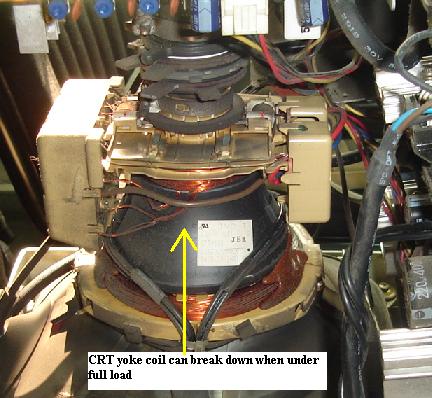

Do you believe that CRT yoke coil can also breakdown when under full load? Yes, I came across couples of CRT yoke coil that check good with the flyback tester (showing 7-8 LED bars) but failed when the Monitor was turned “On”. The display that I saw was a narrow picture (horizontally) and curved inward. First I thought it was some other circuits (like a faulty B+ and horizontal size circuit) that causing the picture to curve inward. After spending countless hours and still can’t find out the fault, I swapped the CRT. You would not believe, the picture worked perfectly fine! What I do, I removed the CRT yoke coil and found a slight burnt mark at the edge of one of the internal winding. You can’t see it from outside, you have to remove it in order to see the inside winding. I was very happy and this kind of discovery really opened my eyes that every electronic component can have the possibility to breakdown when under full load.

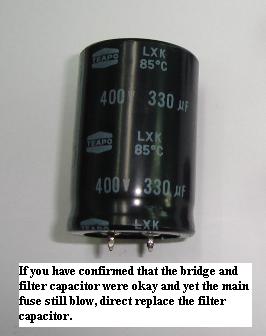

Next is the main filter capacitor, the normal value use in Monitors SMPS power supply is 220 microfarad 400 volt. It has the exact same symptom as when the bridge breakdown which is the fuse will blow when the Monitor is switched “ON”. Checking the faulty filter capacitor with analog, capacitance or even with ESR meter won’t reveal any signs of a capacitor failure. Only by using an insulation tester I could clearly see that the panel shows a shorted reading when the ready button in insulation tester was pressed. This type of faulty electrolytic capacitor only can be detected when few hundreds volts (not more than 400 volts) applied across it.

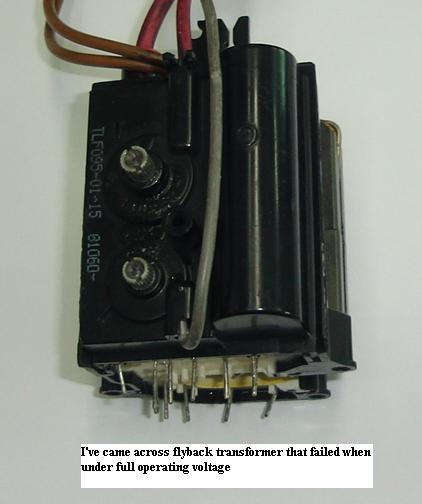

Flyback transformer- Using just a flyback tester to test the flyback primary winding can’t 100% guarantee that a flyback can work when under full load. I’ve seen flybacks that test good but failed when the Monitor was turned “ON”. Although the flyback breakdown when under full load was not very common, once in a while I do come across some! The flyback primary winding checks good but when the Monitor was turned “On” the power supply just cycles (the output voltage going up and down). When a new flyback was installed, the Monitor works normally. If you read my previous article, you will know that I’m using a light bulb to confirm whether the flyback primary winding is okay or not.

Variable resistor (VR) and preset will only give problem when after few years in service. If lots of dust accumulates in the internal area of the variable resistor, it can create intermittent problem or even breakdown when under load. Since variable resistor is easy to get and cheap, you just have to direct replace them if you suspect the VR is the cause of the problem. Intermittent VR problems also mentioned in my previous article please refer to it for more information.

Integrated circuit (IC) just like other semiconductor devices can breakdown when under full operating voltage. You can’t test an IC with a normal tester and if you suspect that the IC is giving problem, you just have to replace it. I still could recall many years back that a Compaq Monitor with the model of V500, the horizontal and vertical oscillator IC always breakdown when after “On” for couples of hours. The bottom display always curls or flips up when the IC is hot. Replacing only the IC solved the Monitor problem. And the fact was the whole batch of this model that used this IC gave the same problem. Since we knew that the new replacement IC won’t last long, we apply heat compound on top of the IC and place a small aluminum shielding on top of the compound so that the IC would not be affected by the heat generated by the Monitor.

Resistors too will breakdown when full voltage is applied across it. If a resistor color band have fade and have rusty leads, I suggest to you to direct replace the resistor in order to avoid unnecessary problem that can happen in the equipment you are repairing. It may check okay with your multimeter but breakdown when under full load. I have a repair friend who told me that he came across start up resistors in the SMPS power supply section that failed when the equipment was “ON”. After directly replace the start up resistors, the equipment was restored to normal operation. He also told me that the problem happened to the whole batch of that equipment. In other words, he changed all the start up resistors in that particular model of equipment.

If you use your normal meter to confirm whether a diode is good or not, you better think twice as I’ve seen silicon diodes that failed when full load was applied on it. I’m not to say you can’t use a multi meter to check a diode, but just that don’t fully hundred percent trust the reading that you measured on the diode. I too use a normal analog meter to check a diode but you need to discern the reading. Let’s put this as an example, if you have confirmed that the vertical section is the cause of the display problem and you have checked all the surrounding components on the section and still can’t locate the faulty part. Then this is the right time to change one by one all of the components in the vertical section which includes the diodes! Who knows may be after changing the diodes the display gets back to normal. I personally came across Monitors that have power cycling problem solved by directly changing the fast recovery diode in the primary section of power supply.

Optoisolator IC can breakdown too when full voltage and signal is applied on it. Carefully observe the IC leads because it can have a rusted leads just like a resistor. It may check good with your meter the LED and the phototransistor, but failed when the Monitor is turned “ON”.

I believe many of you already own ESR meter to check electrolytic capacitor, but do you know that sometimes you may missed a bad cap. I encountered a Monitor where the display pincushion out when the Monitor gets hot. I have scanned the e-cap at the pincushion circuit with ESR meter but just could not locate the fault. The e-cap tested good with ESR meter. There was only one e-cap in that circuit. Only by directly replacing the e-cap, the problem solved. I used analog, digital capacitance and ESR meter to compare the good and the bad one but the reading looks the same on all meters. In other words, if you feel that the component is the cause of the problem, just directly replace it even though you have the best tester in the world!

Small capacitors like the ceramic, mica, ceramic resin, and etc also have the tendency to breakdown when under load. One of the most common type that breakdown in Monitor is the ceramic resin type. It checks good with analog and a digital capacitance meter but immediately fail when the Monitor was turned “On”. This cap is located at the G2 line at the CRT board. It will usually cause no display symptom but with high voltage. Directly replace the capacitor surely solve the problem. Be aware that a missing heater voltage or a defective may cause similar problem too. If the G2 voltage still remain low even though the screen voltage at flyback transformer already set to the highest-suspect this ceramic resin cap. By the way if you come across those small caps that had darkened body, I recommend you to change it even though it shows a good reading checked by your meter. Think about it, if the ceramic resin capacitor can breakdown in the G2 line when under full voltage, it can also breakdown in other electronic circuit too. If you repair LCD Monitor you will know as the ballast capacitor located near the lamps connector are using ceramic resin type capacitor as well.

Transistors just like any other electronic components may turn faulty when full voltage or signal are applied across it. Using freezer/coolant and a hairdryer will usually find out faulty transistors in electronic circuit. Among all the electronic components, the highest breakdown was the transistors.

Do you believe that even a voltage regulator also can breakdown when under load. There was one case in this Gateway EV700A Monitor where the problem was power blinking. I thought it was power supply fault but turned out to be a defective in the voltage regulator located at the secondary side. The voltage regulator was supplying 5 Volts to the CPU and if this voltage cycles the CPU will send a feedback through an optoisolator eventually causing the power supply to cycle too. Measuring with meter you get the 5 volts output from the 7805 voltage regulator (with the output pin disconnect from the circuit-off circuit), if you connect a 12 volts automobile light bulb as a load the voltage will drop to about 1-2 volt! A good one will cause the light bulb to lit and have a steady 5 volts output.

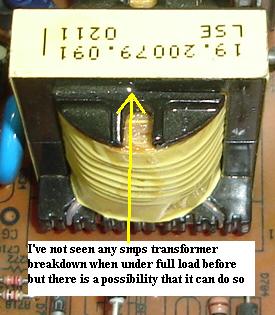

SMPS- The reason I write switch mode power transformer (SMPS) last is because I’ve never come across any of the SMPS transformer that breakdown when under full load from the first day I join electronic repair line until now. It is either shorted or in working condition so far that I have came across. May be some of my readers have experienced before a SMPS that breakdown when under full load. I won’t be surprise if you tell me that SMPS can breakdown under load because it is just like other electronic components. It can have the possibility to breakdown due to bad insulation caused by the heat generated by the transformer itself. May be one day I may experience it!

Conclusion- After reading the above article, I guess you will have higher chances to successfully repair equipment. Don’t give up on repair easily; try directly change the suspected component first even though the component tested good by your faithful meters. I know that every electronic repairer should trust their meter but somehow, sometime the electronic components just need to be replaced to see if the circuit work again. Electronic components that breakdown when under load although might not happen to every equipment, it can happen to any equipment! One more thing I would like to let you know is that there is no best or 100% perfect tester to check electronic components. The best tester is still the equipment itself. For example if you want to be sure that the flyback transformer is 100 % working, the best is to install it in the Monitor itself and switch it “On”. The Monitor will test the flyback primary winding, secondary windings, internal diodes, internal capacitor, flyback divider and etc. If the flyback breakdown it will show you a sign like arcing, blur or even shutdown. Hope you get what I mean. Okay, that’s all for it. May there be many blessing to you and family. Have a great and a wonderful day!

|

|

Copyright@ 2006-2014-www.ElectronicRepairGuide.com All Rights Reserved