|

Don’t burn in test any electronic equipment without supervision.

I’m saying it again “Don’t burn in test any electronic equipment without supervision”. Why did I mention it two times? It is because if any electronic equipment left unattended (no supervision) for a 24 hours burn in test, if something goes wrong with the electronic circuit, the equipment may caught fire and it can burn down the whole office and etc. I always have some extinguisher standby in my technical department and just in case if there is a fire we can put the fire off in the shortest time. I won’t let the equipment that I have repaired to run without anyone in the technical department. We do not know how reliable and how good an equipment design is (there are so many unreliable or cheap equipment in the market) thus we got to take notice about this matter.

Inform the customer about the repair charges first

If you are in the electronic repairing business, one of the most important things that you need to do is to inform the customer first about the charges of the repair otherwise you may end up quarrelling with the customer over the price charged and lose the customer. Your business may be affected and tarnished if the customer spread around about the nightmare incident in your company. In order to avoid argument, write a black and white letter and sent/fax it to your customer, once they agreed then only proceed to repair the equipment. Although this subject (about charging customers) is a bit subjective, I believe you can sort it out handle it in a professional manner.

Laser warning

If you are dealing with equipment that uses laser diode such as laser jet printer scanner assembly, CD Rom, DVD, VCD, and other laser related equipment, you must abide the warning of the laser in the equipment you are troubleshooting. Ignorance can bring disastrous to your vision especially your bare eyes are directly exposed to laser ray without you knowing it. Study all the safety rules about handling laser equipment and how to avoid your eyes being exposed to the laser ray and at the same time you can perform the troubleshooting and the repairing job.

Not having the right equipment

I came across lots of technicians that only use an analogue meter to do the electronic troubleshooting work. They don’t even have a digital meter! To them an analogue meter is already adequate but in actual fact they have missed out something good in their life. I know that sometimes it is hard to convince these technicians to accept new things in their daily routine work but the changes that the new technology have brought really can make someone to save their troubleshooting time. Example, the time before end of the 90’s, many electronic repairers test electrolytic capacitors either with the help of analogue or from a digital capacitance meter. Do you know that both meters of testing the electrolytic capacitor can mislead you into believing that a bad capacitor is good. Your precious repair times were wasted and at the end you can’t find out the culprit. We need different type of meters to tackle different type of problem or components. By using only one or two meters, you are only limiting yourself to quickly find out the fault fast. If you don’t have any ESR meter and wish to get one you may click here.

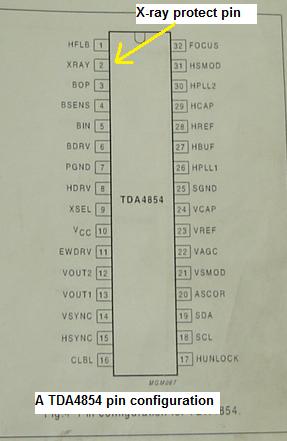

Don’t modify the X-ray protection circuit

If you are repairing the CRT TV/Monitor, I’m sure you have come across before the problem where the set shutdown once the power is turned “On”. There must be some reasons or a defective component or circuit that make the equipment to shutdown. Some call it as “High Voltage Shutdown”. The equipment shutdown by itself was due to high voltage (24 KV) suddenly shot up. A bad flyback transformer, increased in B+ voltage, open circuit in holddown/safety capacitor and some other reasons can cause the set to shutdown. The x-ray protection circuit was designed in the TV/Monitor circuit in order to detect any abnormal high voltage present in the equipment. If there is no x-ray protection circuit in the equipment, the high voltage may shoot up to 30 over Kilo Volts and the X-ray produced will be very harmful to the user.

Now your job is to find out the cause of the problem and please do not take any short cut in modifying and defeating the purpose of this sensitive circuit. If not the user will be exposed to X-ray emission without him or her knowing it. A prolong exposure of such dangerous ray could cause cancer in their body. If you can’t repair the problem juts send the set back to the customer or send it to the distributor for repair. Please think of the consequences before you defeat the original purpose of a circuit in any electronic equipment.

I believe there are more than 10 mistakes that you should avoid but with this information, you should by now know how to handle each mistake and be a good and a successful electronic repairer. Take care my friend!

Learn How You Can Become A Professional LCD Monitor Repairer

|

|

Copyright@ 2006-2014-www.ElectronicRepairGuide.com All Rights Reserved