|

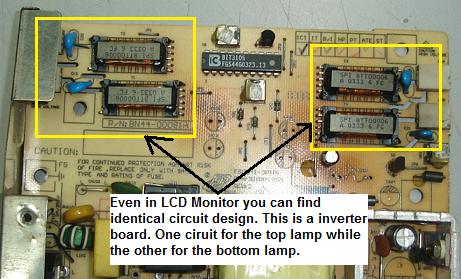

Using Comparison Method to Solve

Electronic Repair Problems

Many

times I solved lots of electronic repair problems by using the

comparison method. So what is comparison method? Comparison method

means that you compare two identical equipment circuits in terms of

measuring resistance; signal and voltage test and see if there is

any different in result. If you get different result meaning the

circuit or components under test is at fault. Thus, with the right

information you had gathered, the chances for you to repair the

equipment is very high.

If a

repair technician or engineer use this comparison method, it is

usually means that they are facing difficulty in finding the

original part number of certain electronic components (may be due

to from a burnt circuit), no schematic diagram available, do not

understand how a new circuit works, missing components (taken out

by some irresponsible electronic repairers), want to solve

electronic problem fast and etc.

I

personally do not always use this method unless I had confirmed

that all the electronic components in a certain circuit or area

were tested good and still not be able to find the faulty parts.

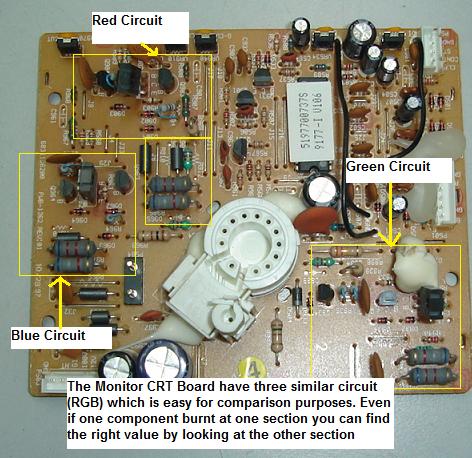

Let’s put this as an example, a Monitor came in with blue colour

missing. This problem normally lies in the CRT blue colour circuit.

It could be a bended blue signal pin at VGA connector, a broken

signal wire in the VGA cable, dry joints in the blue circuit,

defective components in blue circuit, faulty CRT socket or even a

bad PC Tube. And also we assumed that the EEprom IC data is in good

order (for your information, a corrupted EEprom data can cause

missing colour too).

If I

have tested all the components that are related to blue circuit and

still could not find the fault, I have no choice other than to use

the comparison method. Comparison method not only has helped me to

locate the fault, it also speed up and save my troubleshooting

time. Some faults were really beyond your understanding as an

electronic repairer such as intermittent tiny hairline cracked in

the circuit; inexperienced tech installed a transistor in the other

way round, tiny solder bridge across components legs and

etc.

With

the caused I have just mentioned above, if without using the

comparison method, you may get frustrated and many troubleshooting

hours are lost and at the end of the day the equipment still can’t

be repaired or worst if the customer want it back urgently. The

pressure is on you and I hope with this article at least it will

lighten up your burden. There are four types of comparison methods

you can use to repair the electronic problems.

The

first method is to use Ohmmeter (preferably analogue meter as I

found it more accurate than the digital meter) to compare the

resistance between the two identical circuit. Power have to be off

and if the circuit you want to compare have some big capacitors, I

guess you have to discharge it before you do any comparison as the

extra voltage in the filter capacitor can cause a misleading

information (different result with the board you are comparing) and

you thought that you have found the faulty section. Set your

analogue meter to X 1 Ohm and start comparing between point to

point of each electronic component. Certain electronic circuit will

only have response when you set your meter scale to higher range

such as X 10 or even X 100. If the results you get have some

differences then put your attention upon the circuit or component

you are checking. Who knows you might have found the

solution.

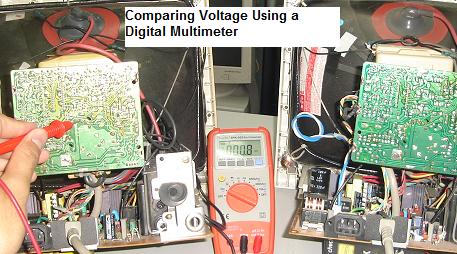

Second method is to compare voltage using a digital meter. I do

not encourage using analogue meter as I found it not really precise

as certain circuit even have a volt different the circuit may not

functioning well. Be extra careful when doing the voltage

comparison test as the power is “On”. Any slip from the test probe

and touch on other components may cause a heavy spark (if you are

comparing the supply line) or even the equipment will totally shut

itself down. If you are not careful, you may end up create more

problems than you can solve. Concentration and know what you are

measuring (comparing) is the key of success in voltage

testing.

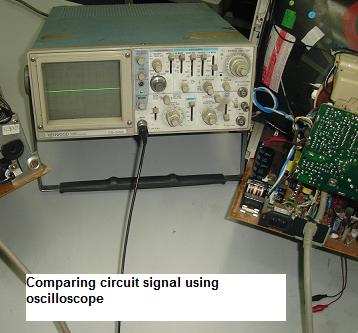

Third, you can use an oscilloscope to compare the signal

between the electronic equipment. You will be surprise that I found

lots of electronic problems solution by comparing the signals. This

method is exactly the same with the voltage comparison method

except that you are now looking at signal and not on digital meter.

Be extra careful too when comparing the board with oscilloscope as

the equipment has to be “On”. Get some books on how to use

oscilloscope as in the long run it really benefits

you.

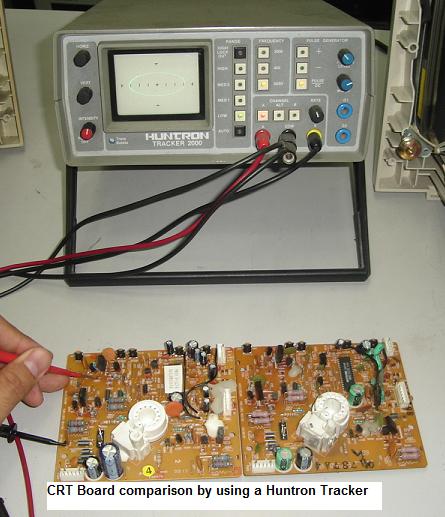

The fourth method is to use

Analog Signature Analysis to compare the boards without power “ON”.

I’m using Huntron tracker 2000 to do the job. This test equipment

applies a current-limited AC sine wave across two points of an

electronic component or circuit under test. The resulting

current/voltage waveform is shown on a signature display using

vertical deflection for current and horizontal deflection for

voltage. This unique Tracker signature represents the overall

health of the part being analyzed. By comparing the signatures of

known good circuit boards to those of suspect boards, faulty nets

and components can be quickly identified. You can get or bid for a

used Huntron Tracker at Ebay dot com if you have lots of similar

electronic boards for repair.

What if I could not locate or do

not have the same equipment or model for comparison? If you have

read my previous post I always mentioned about the emphasis on

friendship among electronic repairer. You just can’t be a lone

electronic repairer; you HAVE to mix around if you want to be

successful in this repair line. I will call my electronic repair

friends to check out if they have any same model of equipment and

if they have, I will ask them to “lend” one for me and will return

it back as soon as possible. Assuming I do not have or can’t get

from my repair friends, I will tell my customers to hold on for few

more days hope there will be a similar equipment send for repair.

Many times after waiting just for couples of days, yes the same

equipment came for repair sent by other

customers.

If everything I have tried and

still no way to solve the problem, I will just let the customer

know. Usually they will accept my explanation and some of it would

send to the supplier for repair of course with a higher

charge.

Conclusion- In electronic repair

one must have the flexibility on how to solve a problem. There are

no certain ways to solve it as electronic problems are quite

dynamic. You have to use the best method to encounter different

problems in electronic. If possible invest in the test equipment

that can really speed up your troubleshooting

job.

|