|

How To Locate Some Good Testing Points In Electronic Circuit

If you are performing an electronic repair task and you did not know how to fully utilize the testing points in a circuit then I believe you have miss out something important in this repair trade. Of course the first procedure is to locate the faulty circuit and then test out the components in the circuit. What if after checking all the components in that circuit and you still could not locate the faulty component?

Do you know that finding out the critical test points in a circuit is equally important as compare to testing electronic components? Test points not necessary have to be at the components pin (IC input and output pins), it can be in any section of the circuit. If you understood the signal and voltage of those test points your chances of solving a problem would be faster. In this article I would not explain how to find out good test points in all electronic equipment but I will show you an easy way to locate good test points in certain boards. Hope after reading this article you will have some ideas where to locate good test points in the type of electronic equipment that you are repairing. Lets’ start!

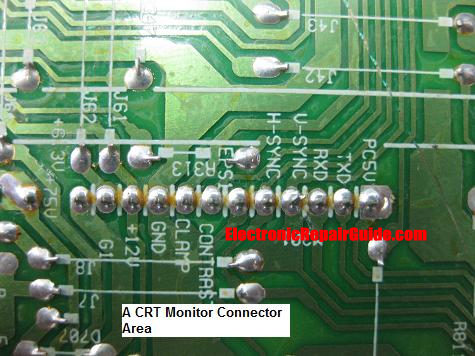

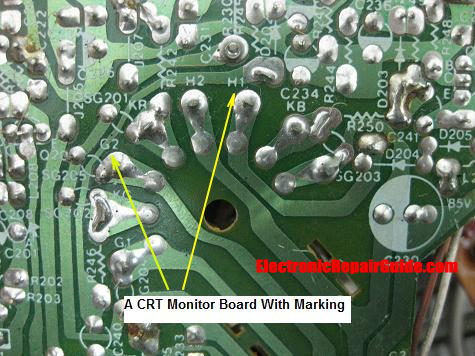

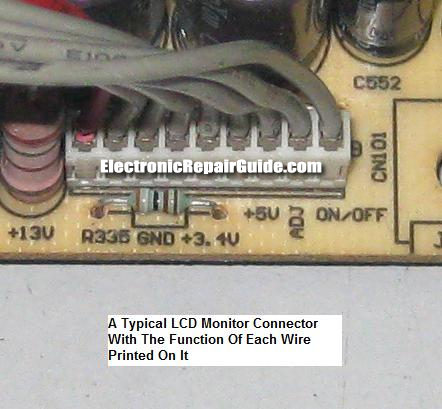

The best test points in any electronic circuit are at the connectors! Yes I’m saying it again-at the connectors! Generally most of the electronic equipment in the market has few electronic boards in it. For example, a CRT Television has the CRT board and the Mainboard, LCD Monitor have the Mainboard, power/inverter board and LCD controller board in it, a Dot Matrix printer have the print Head, Mainboard and power board and etc. These boards are connected using cables or wires and many of the manufacturers would print out the meaning of each wire.

For instance, in a typical CRT Monitor board, at the connectors you could see H sync, V sync, clamp, ground, G1, heater voltage (6.3 volt), 12 volt, contrast, 75 volt and etc. All these are the good/important test points that you should not ignore. You may find some good test points at the CRT board like the G1, G2, R, G, B, and Heater. Understanding the voltage and signal of these points could easily helps you out in your repair work. Assuming the complaint of the Monitor is no display and have high voltage, what you need to do is to place the meter probe at the heater point (6.3 volt) and check if the voltage is good or bad. If it good then proceed to check on other circuit and if it is low or missing then you now have a clue of where to start troubleshooting. When doing the troubleshooting work, one cannot simply test all the circuits and all points. In the long run you are just wasting your time and you have to be precise on where to start probing and the connector area are the best test points for you to get information.

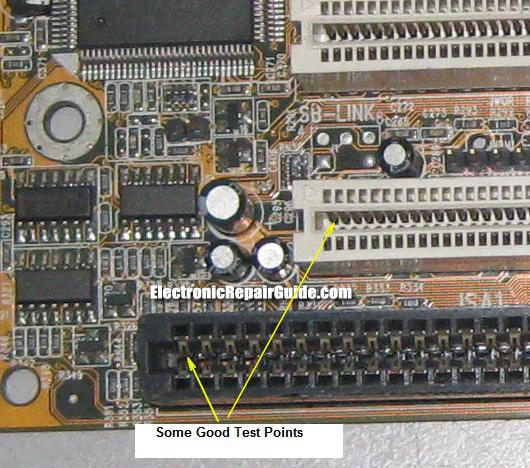

If you are doing motherboard repair and have the schematic for it then the card SLOT in the motherboard could be good testing points too. You can test those points with meters, scope or even logic probe if you have the information of all the pins! Don’t limit yourself to only connector test points, in fact you can look beyond that just like the case in the motherboard (test points at the card slot).

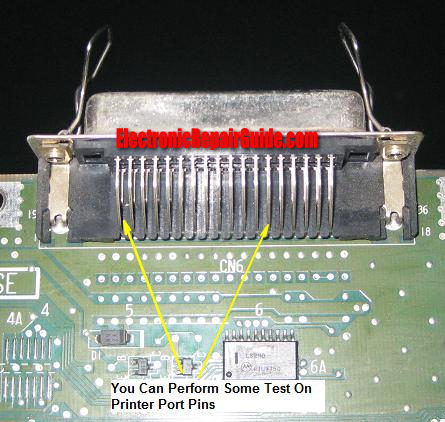

For your information, not only you can test on the motherboard slot, you could also test on the printer port pins if you are repairing Printers.

Well it is not easy if you are first time in taking down all the result. It requires your patience and your precious time. Let me tell you this, nothing comes easy in life. One has to sacrifice his time and then he can expect good returns from what he had done. All these require hard work!

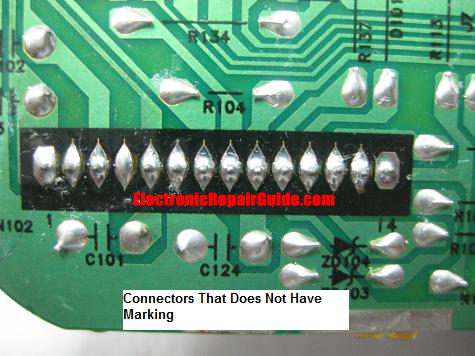

Question- What if the connector’s area does not have any marking on it?

This is the reason why I always ask you to write down information from good working equipment. At least now (assuming you already wrote down the test result) you have something to refer to as compare to when you do not have information at all. You will be in the losing war!

The next solution for this problem is the training/servicing manual and schematic diagrams. With the help of these manuals and diagrams you can easily locate the test points because it usually show you what are the voltages, signal and etc at those points. There was a ERG member who said this “One have to spend some money in order to make money”. I totally agree with him. If the manuals or diagrams that you are seeking could help you to solve your problem then why not invest in it and when the problem solved you could charge your customer and you can keep the manuals and schematic for future reference too. It will pay itself back!

Conclusion- If possible gets some good electronic equipment and write down all the result from the test you have performed on the test points for future reference. Somehow one day you may come across electronic boards that do not have any marking at the connectors and by referring to the test result that you had wrote it down earlier, at least it could shed some lights at where to start troubleshooting. Just to let you know that as an electronic repairer one must be dynamic in thinking and not static especially dealing with many different types of electronic circuit.

Dynamic means you create your own way of testing and find your own test points in the circuit you are working on and because of this dynamic thinking you will excel fast. You have to explore beyond my articles that was sent to you every month. Static means you are wholly dependent on book/article information. That means if there is a new problem you are facing you would give up easily because the information provided by the books/articles have limitation. You have to put more effort in finding your own way or solution to successfully solve electronic circuit problems.

Hope you have enjoyed this article and will be seeing you again next month. Take care and God bless!

Click here to learn how you can become a Professional in Testing Electronic Components

Click here to learn how you can become a Professional in LCD Monitor Repair

Recommendation:

Recommended Mr Kent Projection Television Repair Membership website-Visit Now!

Recommended Mr Kent LCD TV Repair Membership website-Visit Now!

Recommended Mr Kent Plasma TV Repair Membership website-Visit Now!

|

|

Copyright@ 2006-2014-www.ElectronicRepairGuide.com All Rights Reserved