|

Some Facts About Troubleshooting And Repairing Mainboard

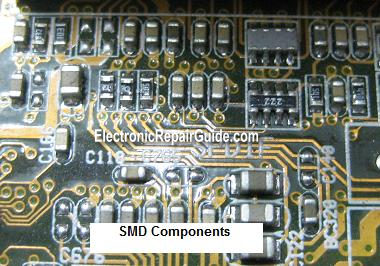

There are three types of Mainboard in the market. The first one is purely using standard components (not Surface Mount Devices- SMD) and generally is considered old already (most probably use in the 70’s and 80’s). Second one would be the combination of standard components and SMD components and the third Mainboard is purely using all SMD components (currently manufacturers producing this type of Mainboard).

Some repair tech call this mainboard as motherboard while to some they called it as cards. Once in a while I have customers came to me and showed me the mainboard that was used in their industry such as printing, PABX system and etc and asked for a solution. They wanted to know whether these types of Mainboards can be repaired or not. For your information, Mainboard can also comes from consumer electronics products such as LCD TV, LCD Monitor, Plasma TV, Computer motherboard and etc. There are some facts that an electronic repairer needs to know before he or she can proceed with the troubleshooting and repairing job.

Fact Number One

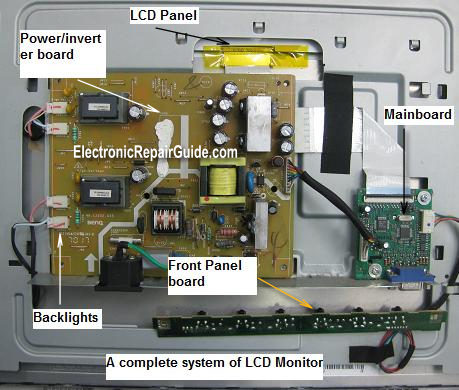

If you want to successfully repair any Main Board, you must get the whole system with it. That means, you need the power supply board and whatever boards that are connected to the mainboard. If the customer just send to you the mainboard, it will be hard for you to repair because you do not know the correct voltage that needs to be applied to the mainboard and without the right voltage there will be no signal waveform for you to check.

Of course you can connect an external source to power up the main board, but you have to understand that certain Mainboard would not run properly if it did not connect to a load. For example, if you are troubleshooting a LCD Monitor mainboard, the power supply/inverter board, backlight and the LCD panel have to be connected in order to get the right voltage and waveforms. Missing either one of the boards may produce different result. Tell your customer the truth that without the complete system, it will be difficult to repair the main board.

Fact Number Two

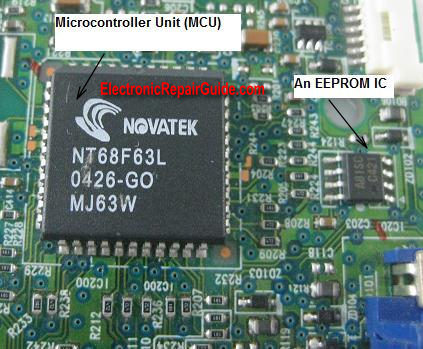

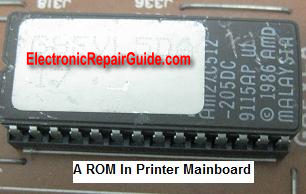

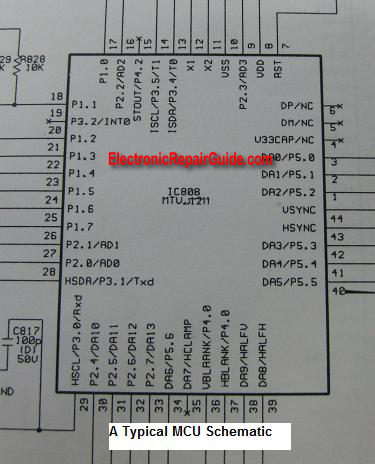

Nowadays many mainboard ICs are using programs to run. Some typical examples are the ROM, Microcontroller Units (MCU) and EEPROM ICs. These ICs have programs in it in order for it to function well. If the programs have corrupted the whole function of the mainboard will go haywire. It will produce weird symptom and very hard to troubleshoot and repair if you do not have the exact program data and the programmer.

Fact Number Three

Schematic diagrams, service manuals and other related information to the mainboard is usually hard to find from the market. If you can locate the schematic diagram, that means it can cut short your repairing time because you will know what sort of voltages and waveforms to be present in the testing points of the components.

Fact Number Four

Many new mainboard are using the BGA(Ball Grid Array) ICs and the normal SMD rework station is not suitable for removing this kind of IC. You need the BGA IC rework station to do this job and this machine is not cheap. Without the proper tools even though you have confirmed that the BGA IC is the cause, there is no way to remove it. If you can’t remove the IC, which means you can’t make the mainboard to work again.

Fact Number Five

Many testing equipment companies like the Huntron, Sencore, Polar, ABI and etc have developed specialized test equipment just to tackle problems in the mainboard. Well, of course you can do the repair job without them, but do you know that if you have such good test equipment in your work bench, it will definitely speed up your repairing time. By comparing a good and a bad board in term of voltages, waveform or even signature analysis, you can easily identify the problem. These specialize test equipment is a big investment and if the board that you are charging does not justify with it then don’t invest in such expensive equipment. It will take years to recover back your investment.

I have a repair friend who told me that he had a Polar test equipment and a high end Digital Oscilloscope. He used it to repair the mainboard from the Aeroplane control tower. He replaced only a cap and charged USD600.00 because the original mainboard price was about USD30,000! With only few of this repair jobs, he already gained back his investment on the high end test equipment.

Facts Number Six

Even though you have the BGA rework station and you have successfully removed the IC, you still need a replacement part. Without the right parts, there is no meaning in removing the IC in the first place. If you have good sourcing of parts for the mainboard that you are repairing, this will guarantee the job can be done. It is better still, if you could locate the exact mainboard that have a reasonable price. Instead of repairing you just sell the whole board to your customer and buy back the spoilt board and salvage the parts for future use.

Conclusion- I’m not writing this article to discourage you to repair the mainboard. These are the facts that we must accept as an electronic repairer when we deal with mainboard. Now, if you have the total solution for the above problems even just for a particular equipment or a model, you or your company will stand tall over your competitors and make lots of money in this repair field. That’s all for this month repair article and will see you again next month. Have a blessed day!

Click Here For My Latest Ebook In SMPS Repair And Read The Real Testimonials From Satisfied Customers

Click here to learn how you can become a Professional in Testing Electronic Components

Click here to learn how you can become a Professional in LCD Monitor Repair

Recommendation:

Recommended Mr Steve Cherubino Laptop Repair Videos For Beginners!

Recommended Mr Kent Projection Television Repair Membership website-Visit Now!

Recommended Mr Kent LCD TV Repair Membership website-Visit Now!

Recommended Mr Kent Plasma TV Repair Membership website-Visit Now! |

|

Copyright@ 2006-2014-www.ElectronicRepairGuide.com All Rights Reserved