Easy Testing Flyback Transfomer Method

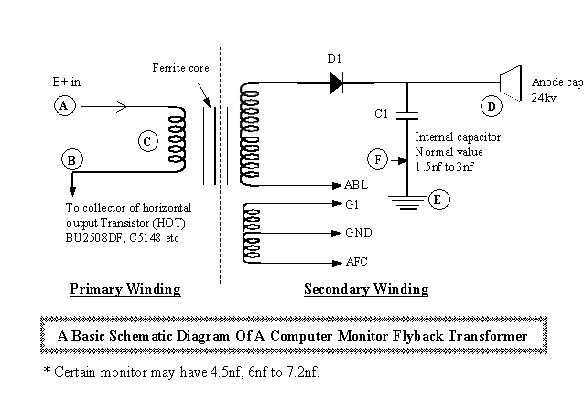

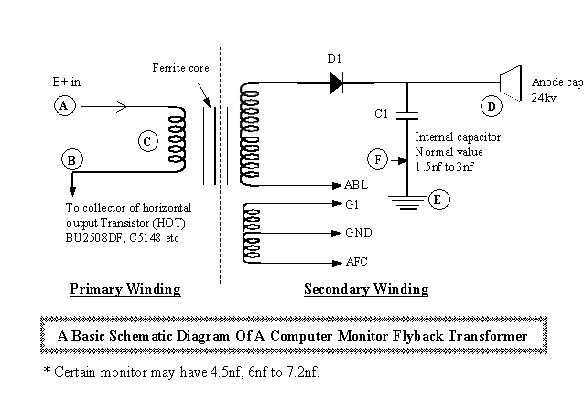

Flyback Transformer schematic diagram

Testing flyback transformer for

computer monitor is complicated if you do not know how to test

it. There are many ways as to why a flyback transformer

fails. I will explain to you nine common faults that you can

find in a defective flyback.

a) A shorted primary winding in the flyback

b) An open, intermittent or shorted internal capacitor inside

the flyback.

c) Flyback Transformer became bulged or cracked and epoxy poured

out

d) External arcing to ground especially at the body or casing of

flyback

e) Internal arcing between windings. It can happen between primary

to secondary winding.

f) Shorted one of the internal high voltage diodes in secondary

winding.

g) Cracked or breakdown in focus and screen voltage divider causing

blur and no display.

h) Flyback Transformer breakdown at full operating voltage

(breakdown when under full load).

i) Short circuit between primary and secondary winding.

Testing flyback transformer will be base on (a)

and (b) since problem (c) is visible while problem (d) and (e) can

be detected by hearing the arcing sound generated by the flyback

transformer. Problem (f) can be checked with multimeter set to the

highest range measured from anode to ABL pin while (g) can be

solved by adding a new monitor blur buster (For 14' & 15'

monitor only.) Problem (h) can only be tested by substituting a

known good similar Flyback Transformer. Different monitor have

different type of flyback transformer design. Problem (i) can be

checked using an ohm meter measuring between primary and secondary

winding. A shorted turned or open in secondary winding is very

uncommon.

What kind of symptoms will appear if there is a shorted

turned in the primary winding?

a) No display (No high voltage).

b) Power blink.

c) B+ voltage drop.

d) Horizontal output transistor or HOT will get very hot and

later become shorted.

e) Along the B+ line components will spoilt. Example:- shorted

secondary diode UF5408 and B+ FET IRF640A.

f) Sometimes it mayl cause the power supply section to blow.

What kind of symptoms will appear if the

internal capacitor is open, intermittent or shorted in a

flyback transformer?

Capacitor shorted

a. No display (No high voltage).

b. B+ voltage drop.

c. Secondary diode (UF5404) will burned or shorted.

d. Horizontal output transistor will get shorted.

e. Power blink.

f. Sometimes power section will blow, for example: MTC 15 inch

monitor.

g. Power section shut down for example: Compaq V55, Samtron 4bi

monitor.

h. Sometimes the automatic brightness limiter (ABL) circuitry

components will get burned.

This circuit is usually located beside the flyback transformer. For

example: LG520si

Internal Capacitor In A Flyback Transformer

Capacitor open

a. High voltage shut down.

b. Monitor will have ‘tic - tic’ sound. Sometimes the capacitor may

measure O.K. but

break down when under full operating voltage.

c. Horizontal output transistor will blow in a few hours or days

after you have replaced it.

d. Sometimes it will cause intermittent "no display".

e. Distorted display i.e., the display will go in and out.

f. It will cause horizontal output transistor to become shorted and

blow the power section.

How to check flyback transformer if a primary winding is

good or bad?

a) By using a flyback/LOPT tester, this instrument identifies

faults in primary winding by

doing a ‘ring’ test.

b) It can test the winding even with only one shorted turned.

c) This meter is handy and easy to use.

d) Just simply connect the probe to primary winding.

e) The readout is a clear ‘bar graph’ display which show you if the

flyback transformer

primary winding is good or shorted.

f) The LOPT Tester also can be used to check the CRT YOKE coil, B+

coil and switch mode power transformer winding.

Dick Smith Lopt or Flyback

Tester

Click here to become a professional in SMPS

repair

NOTE: Measuring flyback transformer resistance

winding , yoke coil, B+ coil and

SMPS winding using a multimeter can MISLEAD a technician into

believing that a shorted

winding is good. This can waste his precious time and time is

money.

How to diagnose if the internal capacitor is open or shorted?

By using a normal analog multimeter and a digital capacitance

meter. A good capacitor have the range from 1.5 nanofarad to 3

nanofarad.*

1) First set your multimeter to X10K range.

2) Place your probe to anode and cold ground.

3) You must remove the anode cap in order to get a precise

reading.

4) Cold ground means the monitor chassis ground.

5) If the needle of the multimeter shows a low ohms reading, this

mean the internal capacitor

is shorted.

6) If the needle does not move at all, this doesn’t mean that the

capacitor is O.K.

7) You have to confirm this by using a digital capacitance meter

which you can easily get one

from local distributor.

8) If the reading from the digital capacitance meter shows 3.0

nanofarad, this mean the capacitor is

within range (O.K.).

9) And if the reading showed 0.5nf, this mean the capacitor is

open.

10) You have three choices if the capacitor is open or shorted.

- Install a new flyback transformer or

- Send the flyback transformer for refurbishing or

- Send the monitor back to customers after spending many hours and

much effort on it.

Some monitors, the internal capacitor may have

the value of 4.5nf, 6nf and 7.2nf.

Note: Sometimes the internal capacitor pin is connected to circuits

(feedback) instead of to ground.

Tv rca flyback transformer circuits usually do not have a internal

capacitor in it. If you have a flyback diagram, schematic or

circuits which you can get it from the internet, that would be an

advantage to easily testing flyback transformer the easy

way.

|