|

How To Create Your Own Flowchart For Troubleshooting And Repairing Purposes

Introduction

So, what is a flowchart? According to the explanation from the Wikipedia- A flowchart is a common type of diagram, which represents an algorithm or process, showing the steps as boxes of various kinds, and their order by connecting these with arrows. Flowcharts are used in analyzing, designing, documenting or managing a process or program in various fields.

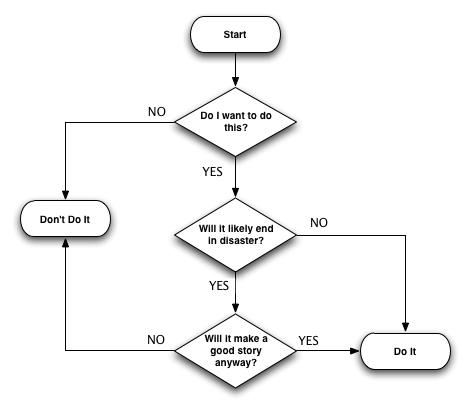

In order for you to easily understand what is a flowchart, just look at the sample below:

A typical example of a flowchart

Is it necessary to have a flowchart for troubleshooting?

If you are just starting out in this electronic repair field, then YES it is necessary to have this flowchart to help you out in troubleshooting purposes. The reason is simple, since electronic equipment consists of many circuits in it; you need a proven step by step way to be able to locate a faulty circuit. You can’t check on ALL circuits in the equipment as this will be a waste of time.

Let’s take this for example, would you check on the power primary section when you already got all the good output voltages at the secondary side of the power supply? If you check on the power supply side, you will be wasting your time. With a proper troubleshooting flowchart, you will know where and what to check so that you will know you are on the right track of finding the bad circuit or components.

Any ideas where I can get the troubleshooting flowchart?

1) Service manuals

Most of the electronic equipment service manuals will have the troubleshooting flowchart in the middle or at the end of the page. Do not think that it is just another common information because I’ve seen some of the flowchart that really consist of juicy tips in finding a fault. Those who created the flowchart in the service manuals knew exactly what were the common problems in the equipment. Study it carefully and don’t miss out any good points from the flowchart.

2) Troubleshooting and repairing books

If you have this kind of hard copy books in your rack, try finding it as I believe there must be at least some troubleshooting flowchart in some of the pages. The book title has to be relevant to practical repair and not electronic theories book.

3) Internet

For your information, there are lots of websites that offer free download on many types of service manuals. Grab this opportunity and download some of the service manuals and begin to do your research on this topic.

How Does An Electronics Troubleshooting Flowchart Look Like?

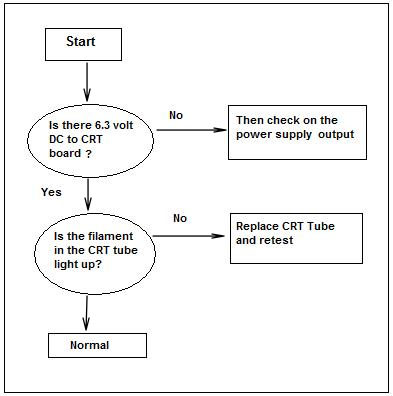

Below is just one of the common troubleshooting flowcharts that shows you how to tackle faults in a CRT Monitor

Complaint-Have high voltage but no display

An example of a more specific flowchart

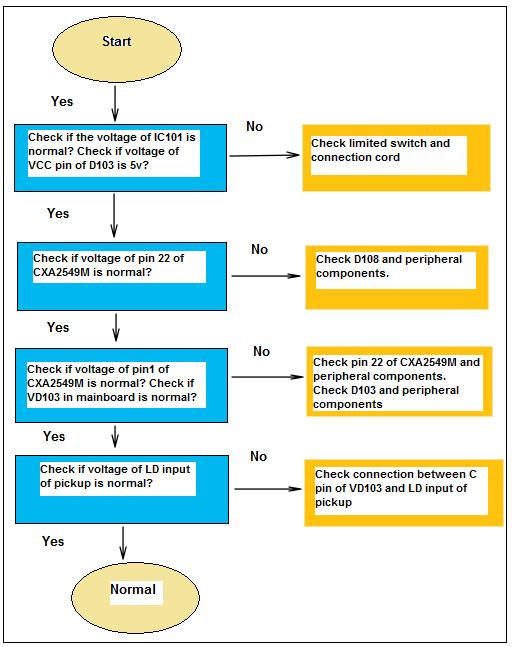

Below is just one of the examples of a specific flowchart for a CD player.

Complaint-Laser abnormal in CD player

A specific flowchart would usually pinpoint to a specific area like “Check that the pin 3 have output waveform” or “Check that the pin 5 of power IC I202 have 16 Vdc” and so forth.

Where to get ideas to create the flowchart?

1) Forum and message boards

Visit forums or message boards that talk about the subject that is related to your repair field. For example, if you are in LCD TV repair then visit forum on LCD TV repair and begin to compile the solution for a particular problem. Carefully read the posting by the professionals and from there you could know as what you need to write in the flowchart. Once you have created the flowchart then it would be easy for you to follow the step by step how to solve a particular problem.

2) From Troubleshooting And Repairing Books or Magazine

Some troubleshooting and repairing books or magazine have a problem and solution section. Gather the information posted by the author and from there you can summarize as what you need to put in into the flowchart boxes.

3) From you yourself!

If you have the time you can always create your own flowchart for reference purposes. Think back, how you have able to solve a particular fault in equipment. Start to draw and put in the steps that had leaded you to find the faulty components. You may be surprised that the next equipment that send in for repair that have similar complaint, you could solve it in minutes with the help of a flowchart that you had drawn.

Should I always refer to the flowchart for every troubleshooting job?

If possible, I want you to memorize the flowchart so that you will be less dependent on it. Have you ever seen any professional in electronic repair that looks on flowchart whenever they perform a repair job? The answer is no because they had kept all the troubleshooting procedure in their mind and when comes to troubleshooting, they are fast in solving a problem.

However, if you are new in this repair field then you are required to depend on the flowchart. Do your best to memorize it after you have created one.

Conclusion- Create your own flowchart for your repair industries if you are not that familiar with the equipment you are repairing. Although it may take some of your time, I could say that the time spent on creating your flowchart could benefits you in days to come. If you are creative enough you can add in real photos instead of the square/round boxes in your flowchart. Alright, this would be my last repair article for this year and hope to see you again next year-all the best to you!

Click here to learn how you can become a Professional in Testing Electronic Components

Click here to learn how you can become a Professional in LCD Monitor Repair

Recommendation:

Recommended Mr Kent Projection Television Repair Membership website-Visit Now!

Recommended Mr Kent LCD TV Repair Membership website-Visit Now!

Recommended Mr Kent Plasma TV Repair Membership website-Visit Now!

|

|

Copyright@ 2006-2014-www.ElectronicRepairGuide.com All Rights Reserved