|

PART I

Interview With Steve

French-Professional Electronic Repairer From Florida

USA

ElectronicRepairGuide (ERG)

- How long have you been in

the Electronic Repair line and at what age you own your first

repair shop?

Steve

- 18 years. I owned my first repair shop at the age of 18. I

actually got interested in electronics at a very young age though.

I was fasinated at how all those “pretty-colored” parts could do

such wonderous things. I was hooked at first

glace.

ERG

- Where is your company

located and what is the name of your company?

Steve

- I currently manage a new repair shop that just opened

in Lakeland, Florida (USA) called "Mid-Florida Electronics,

LLC". This shop is an expansion of the business

I've worked for the past 8 years. I've always run the electronic

repair department and we have grown to the point where we needed

our own storefront and repair space. And that's where we are now.

It may be a "new business" but it's far from new, only a new name

and location.

ERG

- What is your education

background?

Steve -

High school diploma is the extent of my formal studies. I took

basic electronics courses in my last three years of high school.

However, I actively work to keep up with technology and to learn

more about the things I already deal with. So, the real answer is

that my usable education is ongoing to this day. That’s the one thing we all share

as repairmen.

ERG

- Does the courses help you

in Electronic repair?

Steve -

In some ways, yes. The thing with the basic electronics classes I

took is that it taught me some basics but it didn’t teach me

anything about how to apply that knowledge to actual working

situations. I already knew most of what was taught in the courses

because I’d been studying and tinkering on my own for years

already. If I wanted to design circuits it would be a different

story. But as it was, I still had to obtain my practical knowledge

in the field, from other technicians, books and on my

own.

ERG

- Have you conduct any

electronic repair courses before? And what is the name of the

courses?

Steve -

I have taught some electronics and repair techniques to others but

never in a formal class setting.

ERG

- Do you have a

website?

Steve

- Not at the moment. Currently I’m an administrator for the website

www.tvrepairtips.org.

If you wish to join you are always welcome to do so. Our

membership is restricted, however, to people currently

working in the television (and monitor) repair business. We

have a forum and a repair tips database. A lot of our members

(such as myself) work on many types of equipment, not only

televisions.

ERG

- Which electronic repair website you frequently visited and why do

you like it?

Steve

- Tvrepairtips, of course. But I am also a member of Spyderman’s

forums for TV repair techs and I regularly read the material on and

sent out by you and some of your related sites. I feel it’s

important to be open and to learn from other repair technicians. I

love to be exposed to new ideas and methods. What better way to

improve your skills?

I’ve also learned some things from sites

like http://shelbytv.resourcez.com/

, http://noahtec.com/ , http://wa6ati.com/ , http://www.e-repair.co.uk/ and

http://www.repairfaq.org/REPAIR/

, to name a few.

ERG

- What are the Electronic

Equipment that you can repair?

Steve -

I repair practically

every type of consumer electronics. Some of the products I work on

include: TVs, home stereos, computer monitors, microwave ovens,

video game consoles, professional audio equipment, DVD players and

more.

ERG

- Which type of Electronic Equipment you consider yourself expert

in?

Steve

- Probably Playstation 2 game consoles. After that, maybe microwave

ovens and home stereo equipment.

ERG

- How much time do you spend

on equipment before you give up? Why do you give

up?

Steve

- Well, Mr. Yong, that’s a hard question to a precise answer to. It

really depends on the value of the equipment. You’ve got to

consider how much you can charge for the repair to know how much

time you can realistically dedicate to any given job. For example,

I don’t mind spending 4 hours when I now the payoff may be worth

it. But if I’m working on a low priced item, such as a VCR, I just

can’t justify spending more than about 45 minutes to an hour

because I know that I can only get $20-25 to do the repair. So it’s

really a matter of value.

That being said, I still find myself

spending too much time on something every so often. Then again,

some repairs are very quick and simple so it tends to balance out

on average. But I try

to get a general idea of what’s wrong as quickly as possible. Then

I’ll give the customer an estimate that will cover the amount of

time and parts I foresee the job taking. Parts cost and

availability is a big factor when deciding how much time to spend

on something. If I find bad output ICs in a stereo receiver, I’ll

check a few preamp and power supply parts then go ahead a quote a

price. You don’t always need to find every bad part to give an

estimate, only the major parts and any others that are likely to

have failed. This can save valuable time. Especially when you feel

the price of the parts might exceed the value of the equipment and

make the customer decline the repair.

ERG

- What kind of test

equipment do you use in electronic

troubleshooting?

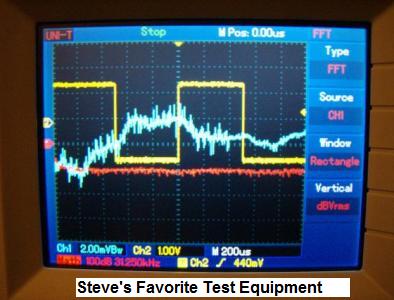

Steve

- My most used pieces of test equipment are: Digital multi-meter

(DMM), oscilloscope and capacitor ESR meter, but I own a large

assortment of test equipment. I feel it's important for a

technician to have and be able to use many types of test equipment.

Without the proper tools, even the most knowledgeable repairman

will be stumped far too often.

ERG

- What’s your favourite test

equipment and why do you like it?

Steve

- I love my new 200

MHZ 2 channel digital storage oscilloscope. It

gives me a lot of capabilities that I wouldn’t have otherwise. The

more types of measurements you are able to make, the better off you

are. And honestly, the beautiful color LCD screen makes me all warm

and fuzzy inside.

ERG

- What was the last

electronic book and magazine you read?

Steve

- I read Nuts &

Volts and Popular Electronics on a fairly regular

basis. I have a nice sized library of electronics books and

magazines that I refer to every now and then but, lately, I’ve been

re-reading the books “Using the Triggered Sweep Oscilloscope” and

“Troubleshooting with the Dual-Trace Scope”, both by Robert L.

Goodman (TAB BOOKS, Inc.).

ERG

- Generally on average how many types of electronic equipment you

can repair in a day?

Steve

- I average around 6 units a day. They tend to be an assortment of

all kinds of equipment.

ERG

- Would you kind to share to

ERG members what are the procedures that you use in order to repair

no power symptom in a Television?

Steve

- I first perform a complete visual inspection. Are any capacitors

oozing, swollen or blown apart? Are there any bad solder

connections in the power supply, on the flyback transformer, any

heat sink-mounted components, etc? Are any components burnt? Next,

I check some major components, such as the horizontal output

transistor, fuses, and main regulator. I look for proper standby

voltages, B+ at the collector of the horizontal output transistor,

activity in the switch mode power supply and see if the

microprocessor oscillator is active. I then use the basic info I’ve

gathered to determine where to go next.

However, with all of these new flat

panel TVs and monitors out there, you’ve got to completely re-think

the way you approach troubleshooting. But in the case of a no power

condition, I also perform an ESR test on all electrolytic

capacitors in the power supply and test semiconductors for obvious

shorts. Also, it’s useful to look for the +5 VDC standby voltage at

the power/standby switch.

ERG

- Does your company have any

contracts (or appointed as an Authorized Service Centre) with any

major brands of equipment?

Steve -

We are an authorised warranty service center for a number of brands

of consumer and professional electronics brands, including

VocoPro, Mackie,

Crate and Ampeg. But there are more that we aren't

able to advertise quite yet because we're still in the process of

transferring the contracts over to the new business name. We are

also actively working on obtaining several more major name brand

warranty contracts.

Speaking of warranty contracts, I

strongly advise any shop to pursue obtaining at least a few. Not

only does that get you on the manufacturer’s referral list and gain

you access to parts and inside information but, it gets you listed

on the company’s website, in owners’ manuals, etc., meaning lots of

free advertising and new customers.

ERG -

How is your repair business

nowadays?

Steve

- We have been quite busy with both wholesale and retail

repairs.

ERG

- Do you encourage

electronic repairers to diversify into repairing more electronic

equipment-If yes then why?

Steve

- An important key to survival in today's electronics repair

business is to have the courage to try new things. If you restrict

yourself to working on only one type of product then you risk

running into a situation where you run out of work and/or miss out

on a lot of great opportunities in the repair industry. Or you get

left behind as trends and technology changes. Don't over-extend

yourself but don't pigeonhole yourself either. The more types of

equipment you can repair, the more likely you are to find something

that you really shine at, can make you money repairing and that

will keep you busy when everything else is slow. After all, we're

all in this business to make money. Fun is fun but the bills still

have to be paid.

ERG-

Do you meet regularly with

other electronic repairers to discuss about electronic problems and

solutions?

Steve

- Only on the Internet and with Don, my other technician. The sad

truth is that most technicians and repair shops view all outsiders

as the enemy. I hate that way of thinking. I can understanding not

wanting your competitors to get “too good” but it really only hurts

yourself in the long run.

ERG

- Do you do your own R &

D to find a better solution in electronic repair, for example like

coming out with your own way of solving a particular circuit

problem?

Steve

- Yes, I often do. Sometimes the answers you need are very hard to

come by or simply not available so doing your own research and

figuring out ways to troubleshoot unusual and unfamiliar systems is

a must. It also makes you a better technician in the end. I’ve even

designed and built several pieces of test equipment to help make my

job easier and the time spent was well worth it.

I’ve shared some of

my designs and test solutions on

tvrepairtips.org.

ERG

- What are the biggest

problems you are facing in the Electronic repair business

nowadays?

Steve

- That’s easy: parts and information

availability. The way I see it, we - as repair

techs - are in a constant battle against the equipment

manufacturers. We reply on fixing their equipment to make a living.

But they rely on selling new units and hate having guys like us

prolonging the life of equipment already out in customers’ homes.

As a direct result, the manufacturers are usually of little help

when it comes to service information and technical advice. And more

and more brands are nearly impossible to repair because replacement

parts are simply not available to us. The problem is that the

customers don’t always understand these things. They assume that we

have access to everything and that every TV (for example) is the

same inside. Nothing is farther from the truth. The truth is that

each and every new make and model means a challenging learning

curve for us as technicians. That’s the way it has always been and

always will be.

To make things worse, the engineers

are constantly redesigning the circuits to keep guys like us on our

toes. It’s a matter of “keep up or catch up” and both can be

difficult to do.

ERG

- Have you come across any electronic equipment that you can’t

repair? And how do you solve it?

Steve -

Absolutely! As much as I’d like to say I can fix anything, the fact

is that no one can do it all. All we can do is try our best and

apply the knowledge and resources we have in new and creative ways.

This is another case where the value of the equipment comes into

play. If I can’t narrow the problem down to the component level (or

if the parts are not available) then I’ll try to quote the customer

for replacement of the entire circuit board. Of course, I try to

avoid that but sometimes it’s the only way.

Another person with a fresh

perspective or different troubleshooting strategy might quickly

catch something that I’ve missed or didn’t even consider to be a

possible cause. So I’ll sometimes let another technician have a try

at it, either in our shop or another. We have ties to several other

shops in town. In fact, we repair a LOT of equipment for other

repair shops; they are some of our biggest accounts. So you see, if

you learn to make professional relationships you will find that

your competition doesn’t have to be the enemy. They can actually be

your greatest allies.

ERG

- How do you promote your

repair business?

Steve

- We have a radio commercial campaign going on right now. We also

rely on our signs, word of mouth, our wholesale repair accounts,

and referrals from other businesses we have ties to. We are also

listed on a number of websites for various brands as an authorised

service center.

Soon we will be starting a targeted

mailing program tochurches, bars, night clubs, hotels,

motels and restaurants. If you’re going to repair

any kind of equipment, look for places that use that equipment in

large numbers. Then you have a potential customer base to go after.

Think of all the TVs in a typical Hotel or sports

bar.

ERG

- Do you have any tips for

anyone who wants or plan to set up their own Electronic repair

shop?

Steve

- Make as many contacts as you can; You need sources for parts and

information. Don’t get in over your head with bills. I will take

time to be where you need to be (as far as income goes) so find a

storefront that you can afford. You can always grow larger as

needed. Treat your customers the way you would want to be

treated.

Spend the money and get the test

equipment you need. And finally, never stop

learning and improving your troubleshooting abilities. No matter

how good you are, you are guaranteed to become outdated if you

don’t actively keep up with technology.

And finally, one of our best moves was

to charge a non-refundable bench fee up front. Don’t underestimate

the importance of the bench fee. It’s paid when the customer leaves

the equipment and helps cover the time and some of the parts

required to give a halfway accurate estimate. Then, if they have

the unit fixed we apply the prepaid deposit towards the repair

bill.

For many years most shops in our area

gave free estimates. I was one of those. But you just can’t afford

to do that anymore. New equipment is taking more and more time to

research and diagnose and we can’t work for free. When you spend

hours just to obtain critical service information and diagnose the

problem then the customer doesn’t want to pay the price, who loses

on the deal? That’s right, the one who wasted all that time and

effort.

Some shops think they are doing the

customer a service to give free estimates. I feel that you actually

do yourself a dis-service with that strategy. Those days are gone.

If they won’t pay the bench fee you know they won’t pay the repair

bill. Doctors don’t give free diagnostics and neither do

we.

ERG

- What advice would you give

to a beginner who wish to join this trade?

Steve

- Learn to use the test equipment you've got in an efficient manner

to save yourself valuable troubleshooting time. If you can find an

easier way to narrow down the fault more quickly then it's well

worth learning to do so. Even the most basic test equipment can be

used in advanced ways if you take the time to learn

how.

But don’t forget to learn the basics,

such as electrical theory. And remember the old saying: “Your most

important test equipment is your brain.” Analytical thinking can

often take you right to the problem much faster than testing random

components. Be curious. Be safe.

ERG

- What advice would you give

to an experienced or professional electronic

repairers?

Steve

- Never stop

learning. There are plenty of books and websites -

such as Jestine Yong's network of repair sites and the one I help

administrate (www.tvrepairtips.org) - where you can expand and

share your knowledge with other repair technicians. Today's repair

world is not the same as it was 10 years ago. And the same holds

true for the future. That's why it's so important to keep actively

learning. You must work hard to keep up with modern technology

because that’s where the future is at - with or without

you.

ERG

- Did you make mistakes that

others could learn from?

Steve

- I’ve made plenty of mistakes. It goes with the territory. One

that I’ve recently learned from is to always show the customer that

their flat panel TV/monitor is working before you allow it to leave

the shop. Those things are easily damaged if they are handled

carelessly or if they fall over. If the customer cracks the screen

while moving it they may think you caused the damage. Or they may

try to blame you, knowing it was their own fault. Showing them the

unit operating will prevent you from being blamed and save you a

fortune and lots of headaches. Trust me.

ERG

- What is your future plan

for your electronic repair business?

Steve

- Our immediate plan is to become more established at our new

location and to finish setting up the new shop the way we want it.

Long-term plans include building our authorised repair status,

increasing our parts inventory, growing our customer base and

reaching the point where we need more

technicians.

ERG

- Would you kind to share your email to ERG members just in case if

they have anything related to electronic repairs to ask

you?

Steve

- mfdsteve1@verizon.net

ERG

- Thanks

Steve!

Steve

- I’d like to thank you, Mr. Yong, for all that you do for your

fellow electronic repair technicians. Thank you for allowing us

this opportunity to be featured in your article. And finally, thank

you so much for your time. Have a wonderful day.

- Steve French (Manager: Mid-Florida

Electronics, LLC. 1527

S. Combee Rd. Lakeland, Florida. 33801

USA

Click Here To Go To Part

II

Click here to become a

professional in Testing Electronic

Components

Go to part

II

|